- Civil Engineering

- Project Management

- Structural Engineering

Scope

Hamburg is planning to increase the capacity of its public transport system by expanding railbound transport.

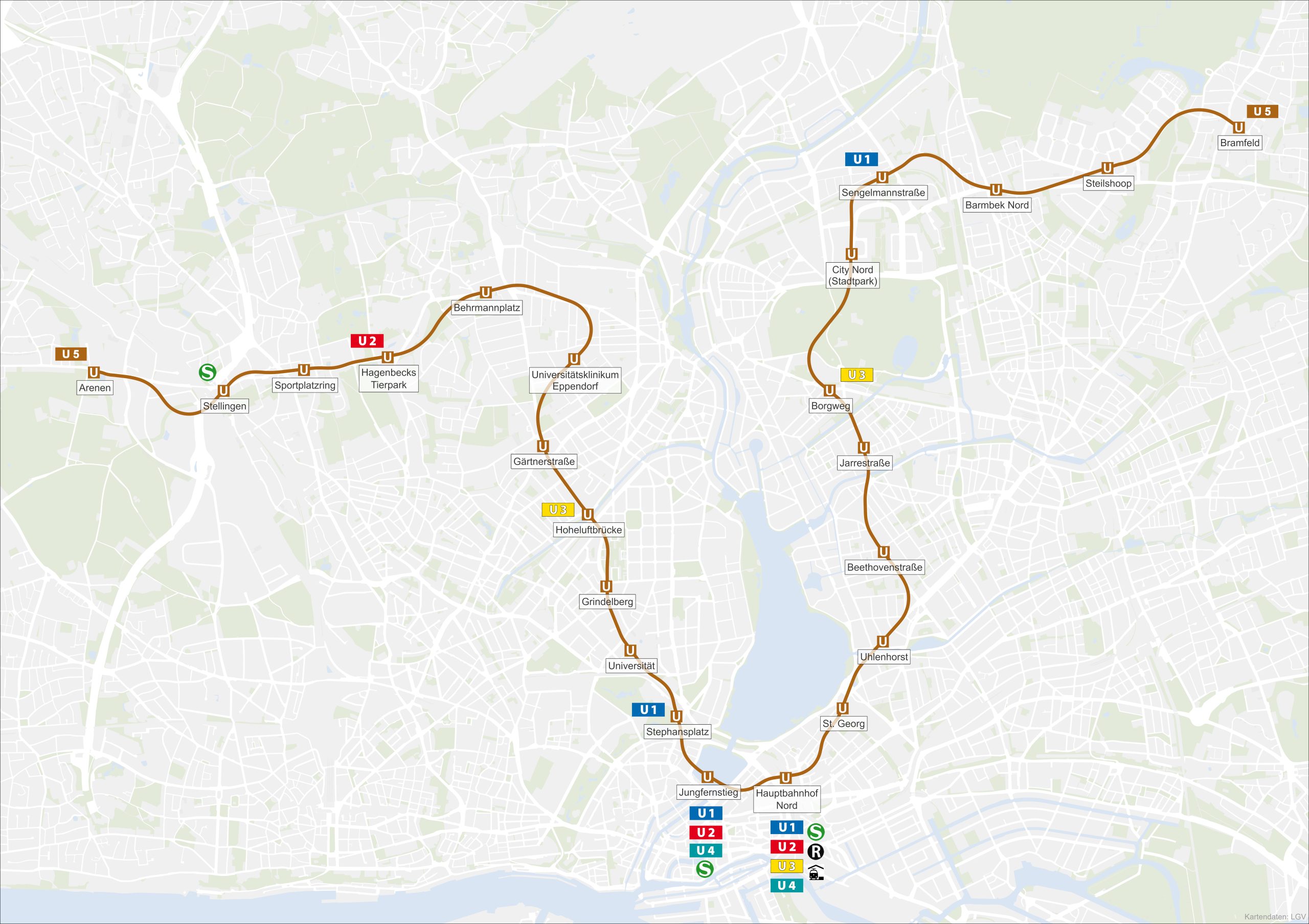

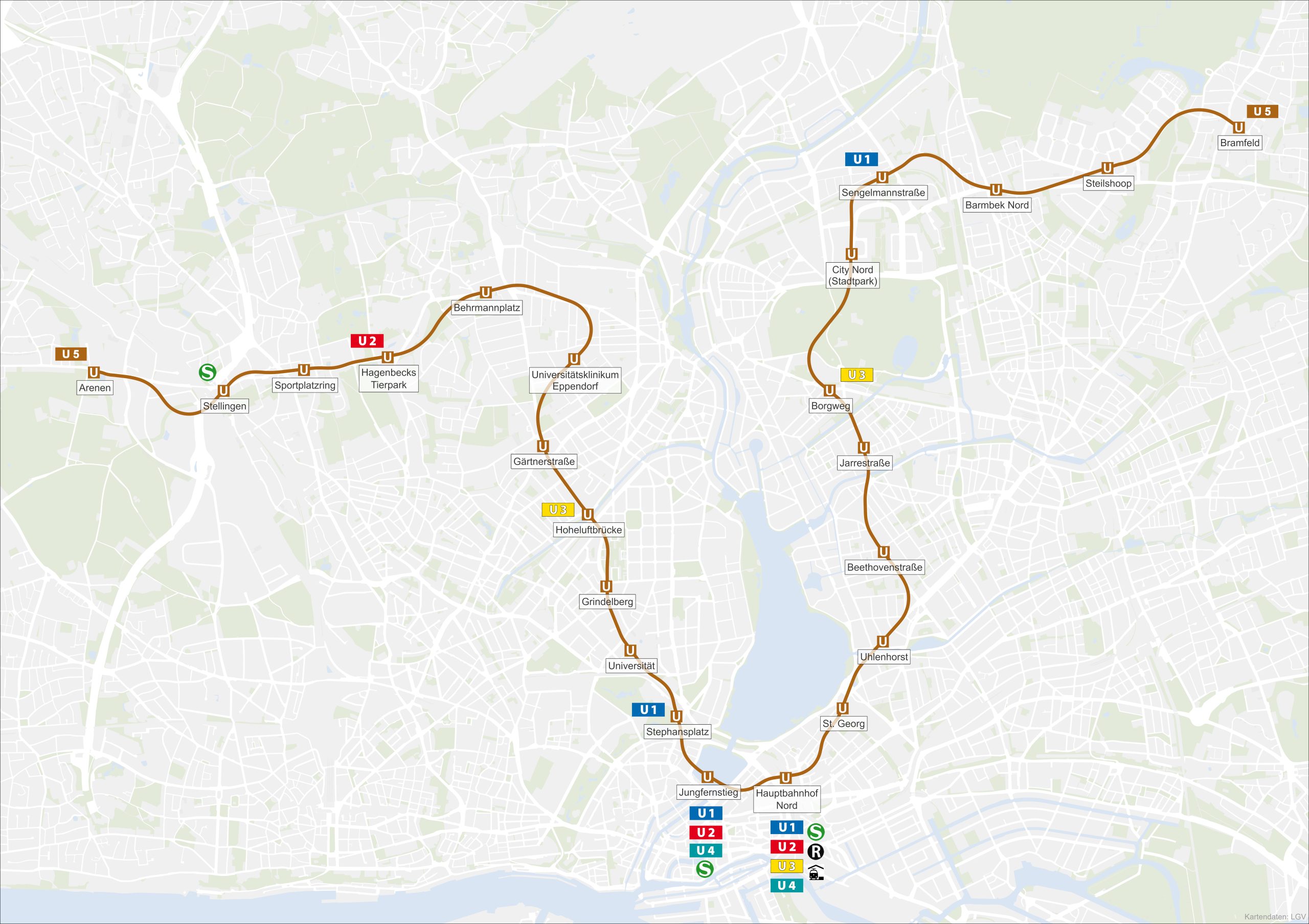

A previous feasibility study has identified areas of high demand for public transport east and west of the Alster to be connected by a new underground line, called U5. The new driverless and fully automated U5 trains, which will run every 90 seconds, will be one of the most modern of its kind in Germany. Along a route of about 24 km and 22 stations, 180,000 Hamburg citizens will get a connection to the rapid transit in walking distance. It is expected that 270.000 passengers will use the U5 daily.

Due to the total length the line is divided in several sections. For each section, depending on the local conditions, the optimum construction method for the tunnel sections and the stations was identified (TBM method or cut and cover method).

While the section Bramfeld to City Nord is already under construction and will start operation in 2033, it is planned that the U5 will be in operation from 2040 in total extend.

The total construction costs amount to approximately 15 billion €.

Approach

Hamburg-based HOCHBAHN AG has commissioned the engineering consortium IGU5M, of Schüssler-Plan Ingenieurgesellschaft mbH, WTM Engineers GmbH and our MERGE partner ISP ZIVILTECHNIKER GmbH, with the design and approval planning for the U5 subway line from the City Nord station to the Arenen station. The route is some 18 km long and has a total of 18 stations.

A key challenge in planning an underground line through inner-city areas is minimising the impact of construction work on residents, road traffic and public transport. To meet these diverse challenges, the BIM method was established right from the start. The BIM method allowed the setup of a structured data storage system for the vast amount of basic data as well as the planning results that were prepared for further planning phases. In addition, optimized technical solutions for often cramped spatial conditions could be developed and clear information for the early involvement of stakeholders can be extracted from the BIM model.

Another focus was placed on sustainability. A strategy to reduce CO² emissions was developed in the early planning phases. In addition to choosing construction materials with the lowest possible CO² consumption, structurally optimised construction pit systems and structures as well as material-saving construction methods were preferred right from the planning stage.

Outcome

The tunnels of the U5 to be designed by the engineering consortium will be mainly constructed by TBM method for two single-track tubes. The stations will have central platforms with concourse levels above and will be designed as a cut and cover construction. The heterogeneously layered subsoil does not allow construction using the classic diaphragm wall and cover construction method in impermeable soil in all areas. Depending on the groundwater levels and the soil conditions, open construction pits with underwater concrete slabs will become necessary at some locations. Anyway, the high groundwater levels require watertight excavations with high tightness requirements to adjacent structures. In particular, the transfer stations to existing subway lines, such as the complex integration of the U5 into the existing Central Station, require a holistic planning approach.

In addition to the challenges in special foundation engineering and tunnel construction, the U5 project also includes planning bridges, architectural design stations, relocations of large sewage systems and integrated road traffic concepts.

Image copyrights used: Blunck+Morgen

Image copyrights used: Hamburger Hochbahn AG