- Civil Engineering

- Project Management

- Structural Engineering

Scope

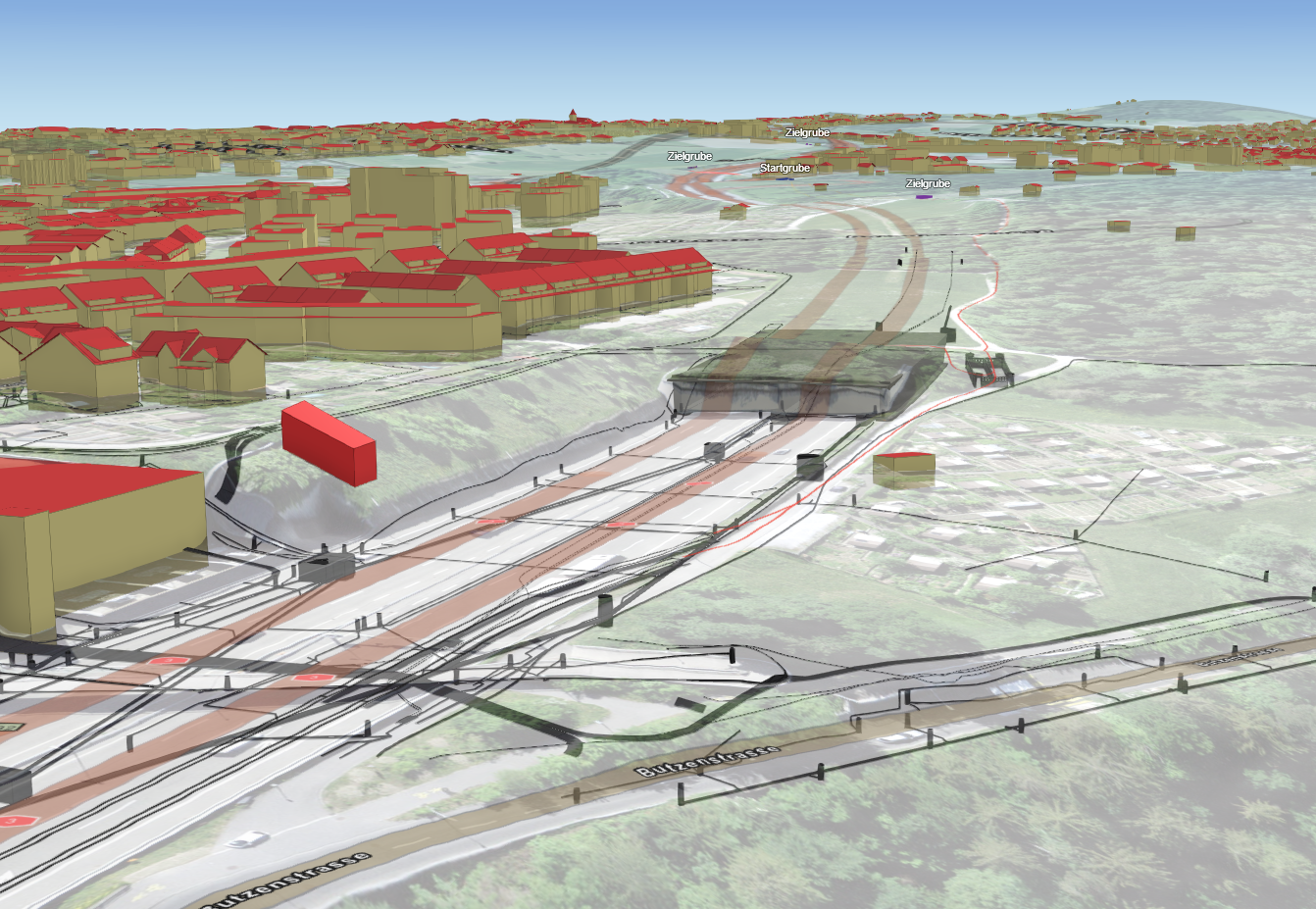

Expansion of the production site to include a mill building and a pellet loading silo – new storage volume is 960 tons.

One of WTM Engineers’ strengths is the holistic view of the handling and storage of bulk goods such as grain. This includes the planning and calculation of the ship’s berth as well as the planning and calculation of the silos and headhouse for storing the grain. This comprehensive approach prevents interface problems and significantly simplifies coordination for the customer. WTM Engineers also offers the planning of waterfront structures or silo facilities separately.

The extension for the Hamm, Westphalia, site is located on the Datteln-Hamm Canal in the immediate vicinity of the existing plant. The new, independent mill has three grain grinding lines as well as raw and finished product silos. The raw product silo has a storage volume of 8,100 m³, the finished product silo can hold a total of 9,750 m³ of flour and bran. The total capacity of the mill is 906 t / 24 h. A loading station was also planned and built.

Approach

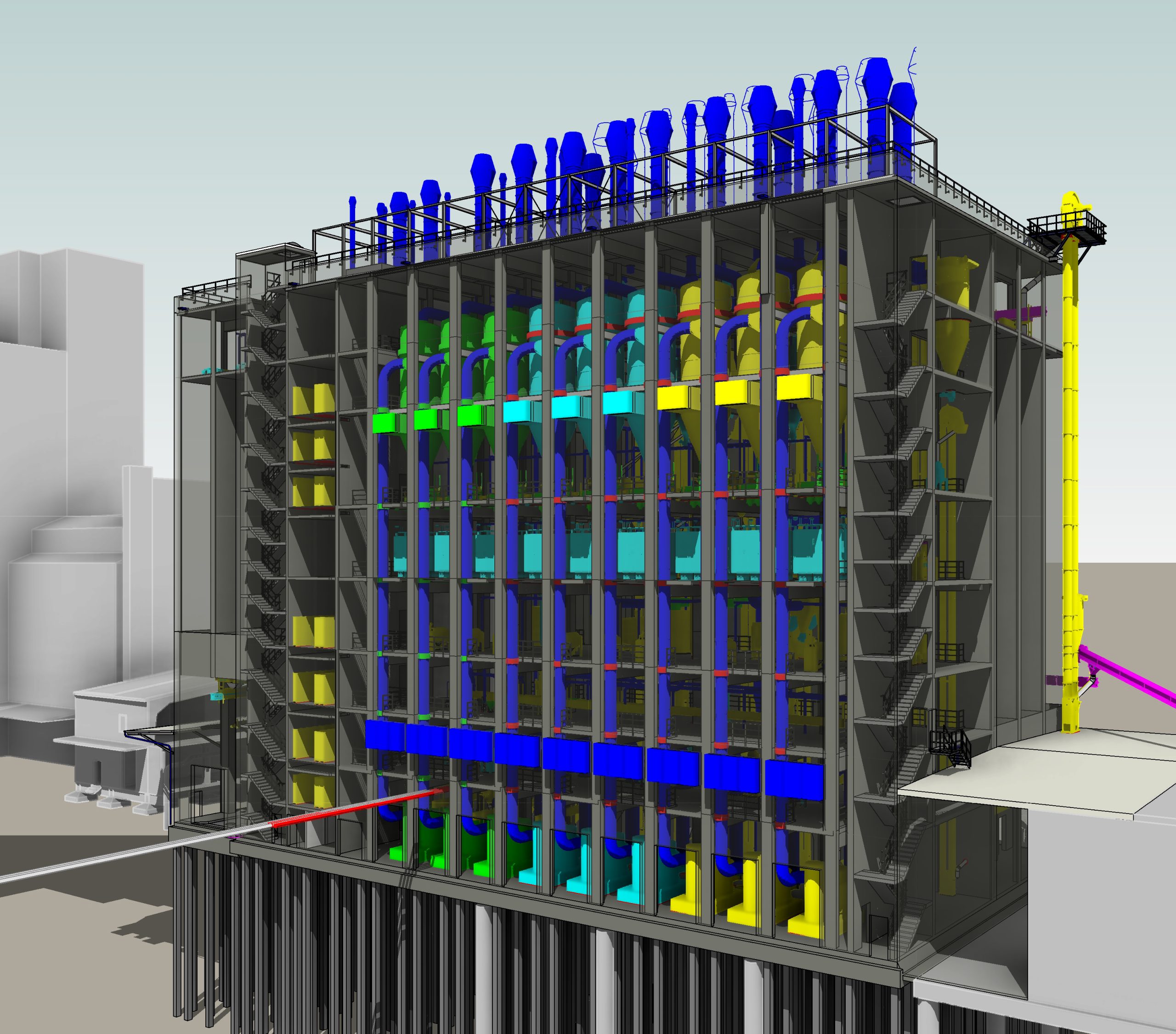

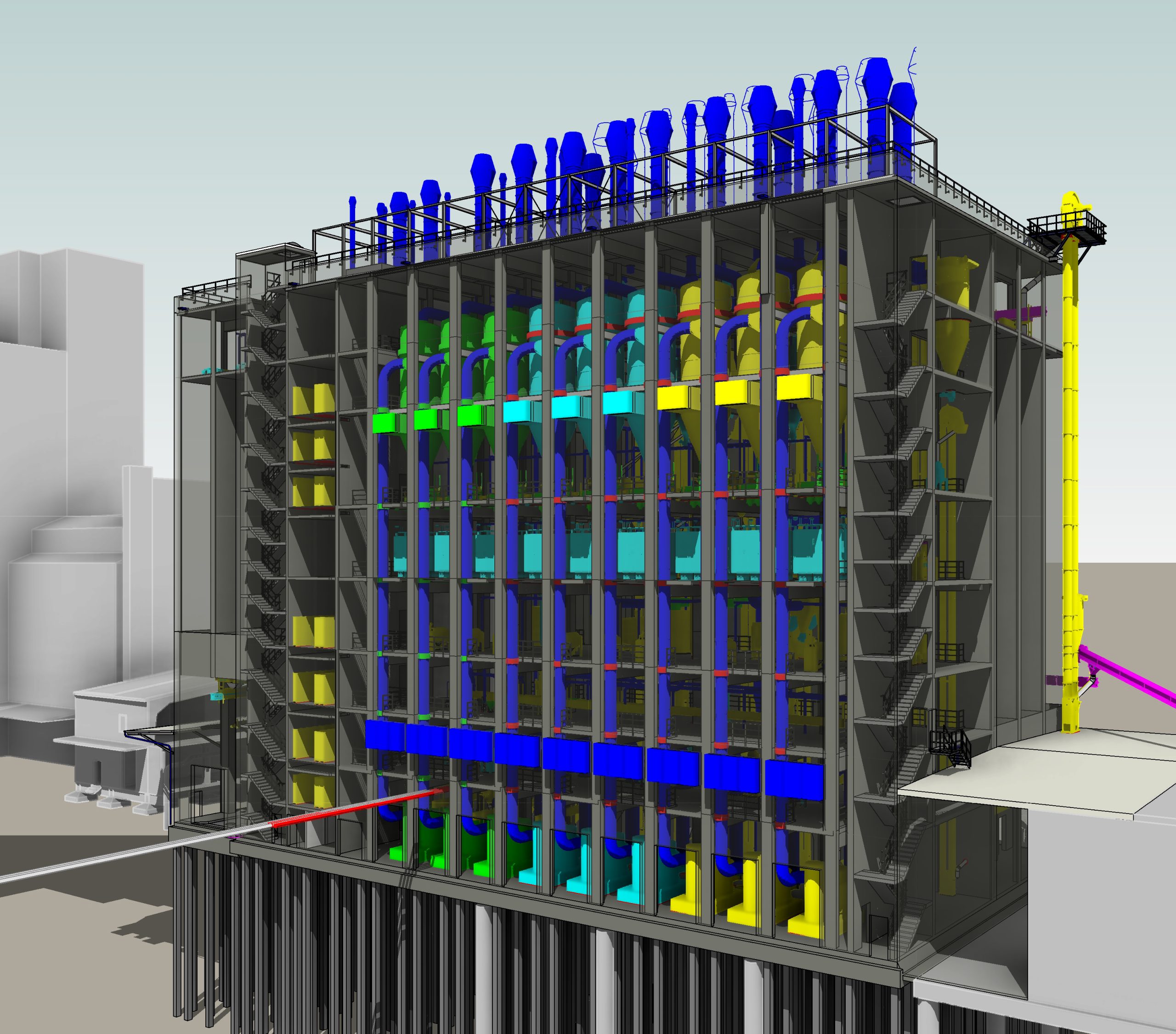

In order to cover all aspects relating to functionality, robustness, structural safety, costs and construction, a BIM model was created and updated as a digital twin from the outset, which contained all relevant information from all specialist disciplines. This included both our own building planning and structural design, as well as the plant and conveyor technology planning provided by the client.

Special hygiene standards in food processing operations require high demands on materials and construction. This applies to surface quality, specially developed details and resistance to routine heat treatments in mill operations. In addition to hygiene standards, the main focus in production was on fire and noise protection as well as tightness in the construction.

Outcome

The mill building is mainly constructed using in situ reinforced concrete.

The walls and supports of the silo cells and staircases were constructed in four sections using the slip-forming method. Due to the direct vicinity to the canal, the loading and unloading of bulk carriers are easy to handle.

Image copyrights used: Bitschnau